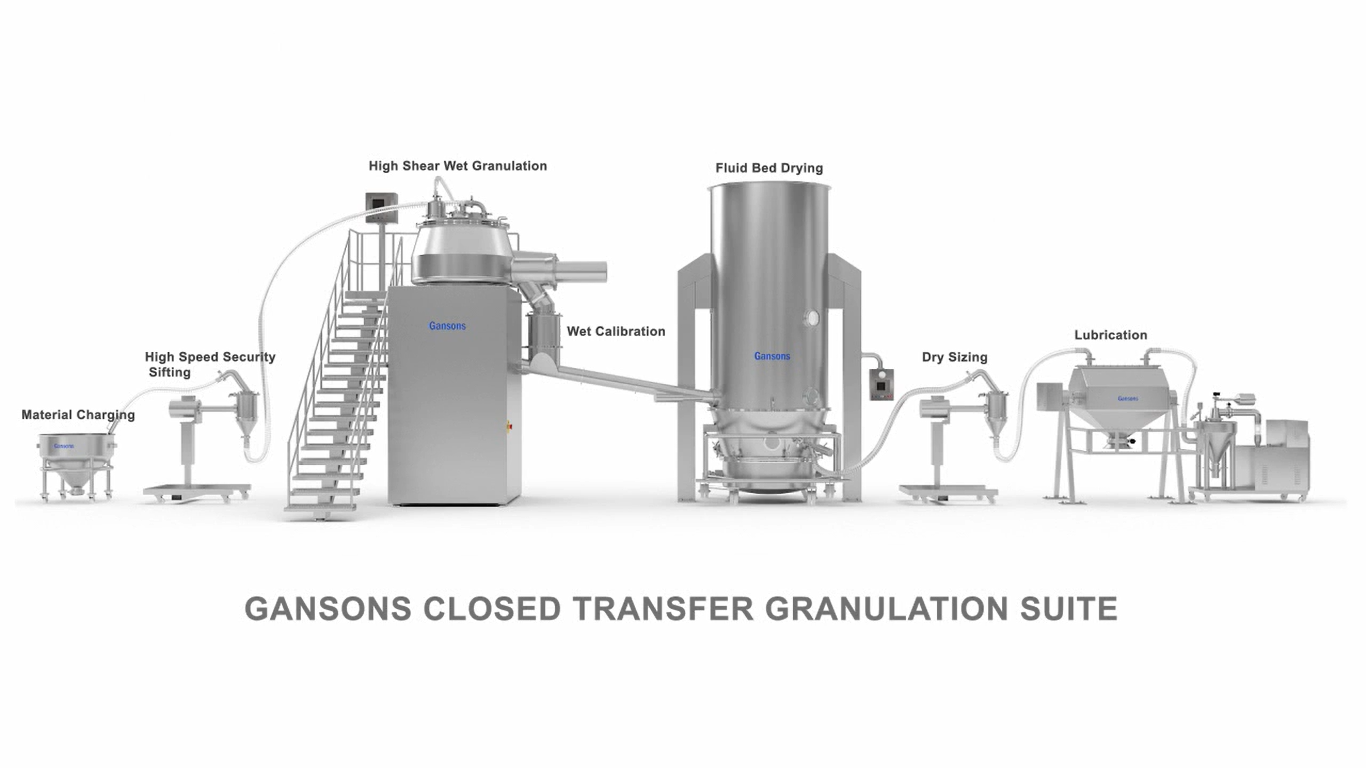

The Gansons Pharma Integrated Granulation Line

Wet granulation remains the most widely used process for production of pharmaceutical solid-dosage forms.

Modern production processes demand an integrated, scalable, reproducible, and risk-free manufacturing solution.

The Gansons Integrated Granulation Suite, called the Force Multiplier® is the preferred wet-granulation solution for the world’s fastest growing regulated pharmaceutical companies.

The Gansons Force Multiplier® facilitates a high, predictable, reproducible throughput with minimized downtime and advanced safety features.

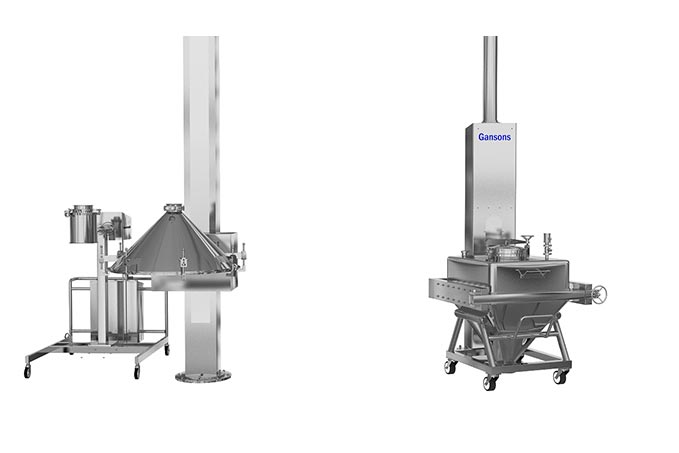

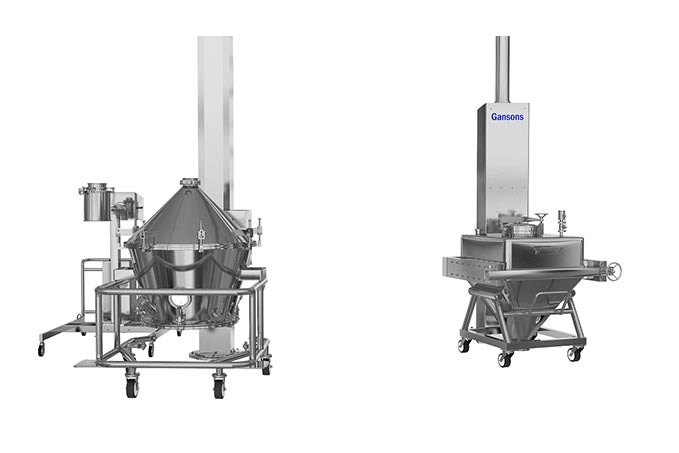

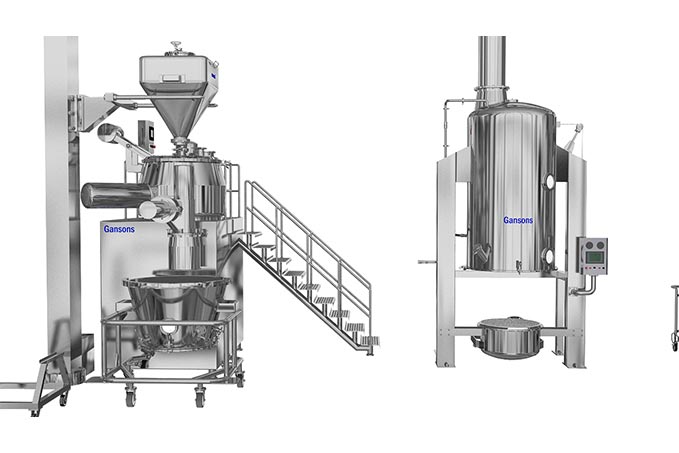

The Gansons Pharmaceutical Integrated granulation line including High speed Mixer & Granulator, Inline Wet mill, Fluid Bed Dryer & Granulator, Lifting device with Inline Dry Mill, and IBC Lift Blender at different sizes depending on customer demand.

Increased Output

• Compact footprint, line-balanced for maximum throughput

• Manufacturing continuum achieved

Intelligent Automation

• Centralized automation platform drives reproducible results

• Reduced human intervention means negligible mistakes and therefore, fewer delays

• 21-CFR Part 11 compliance for data integrity and storage, ALCOA+ compliant

• Pharma 4.0 enabled software, IoT enabled

• Smart graphs for lot reproducibility

• Responsive, ergonomic, intuitive interface

• 3-modes with multi-level password access

Improved Safety

• Closed transfer of materials ensures minimal operator exposure

• Safety interlocks

• 12-Bar shock-resistant designs available for structural integrity and containment.

• ATEX rated (flame proof) designs based on zoning requirements. All components are by default compliant to a Zone 2/22 production environment.

• All contact parts in SS 316L, or FDA approved materials (gaskets, seals, filter bags etc.)

Predictable scalability from R&D to production

Cleaning convenience

WIP system for in-situ cleaning (can be recipe driven)

Fast changeover

Site Installations

Compliances and Certifications