Gansons inONERD – The Best Pharma R&D Equipment

An all #inONE laboratory processing equipment

Gansons inONERD is the world’s first 10-in-one, solar power enabled R&D processor, designed to perform several operations in one fully contained system. This modular, portable, tabletop model is capable of handling tablet coating, granulation, fluidized bed drying, milling, sifting and blending – all in one.

The Gansons inONERD has been developed for the advancement of pharmaceutical research and development of powders, tablets, and other solid dosage forms.

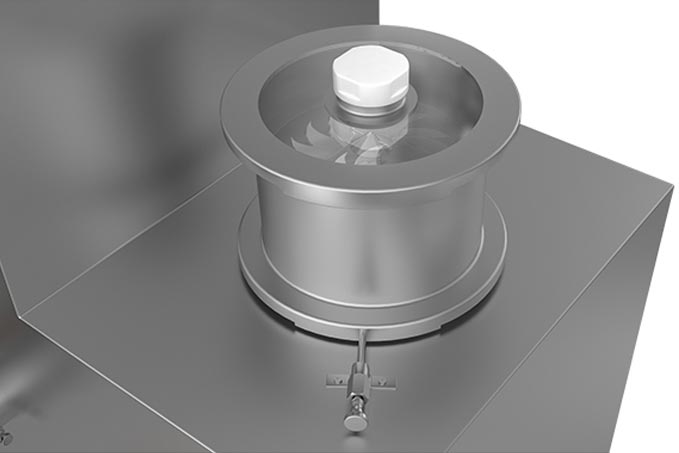

The GansCoater®

Geared to handle lots of 50 to 300 g. Featuring the R-mini nozzle, the laboratory-scale of Gansons’ proprietary GHPN IIIRD nozzle, Watson Marlow peristaltic pump, Gansons proprietary baffles and signature smooth, perforated pan.

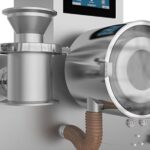

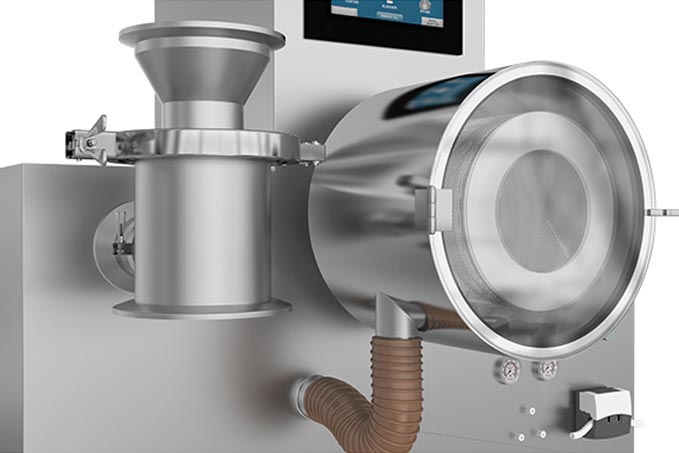

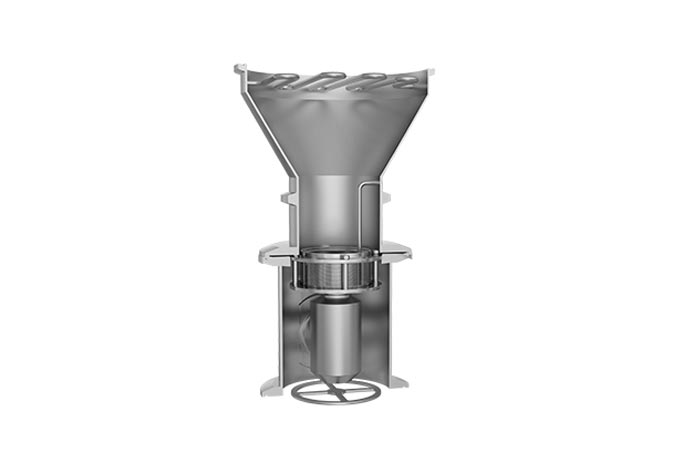

Hanningfield Uni-Mill®

A simple and versatile system integrated with the Gansons inONERD for particle sizing. The particle sizing Hanningfield Uni-Mill® has a gearbox-driven impeller, rotating inside a conical screen. This principle achieves comminution primarily by compression and shearing of the particles between the impeller and surface of the screen. The detachable mill head can be autoclaved or interchanged with the sifter head for sizing.

In-built Air Handling Unit

Isolator Compatible

Suitable for oncological and hormonal products.

Gansons High Shear Mixer Granulator and SuperGran®

For wet granulation, the inONERD is equipped with Gansons High Shear Mixer Granulator of 0.5 L capacity. Our proprietary impeller design allows homogenous mixing and incorporation of binder for uniform granulation, that can be scaled up to pilot batches and beyond.

Hanningfield Kwik-Sift®

The gentle centrifugal sifting rapidly separates undersized and oversized particles. The effective sifting action can separate extraneous material as fine as a human hair strand! The spoiler arm also gently delumps cohesive powders.

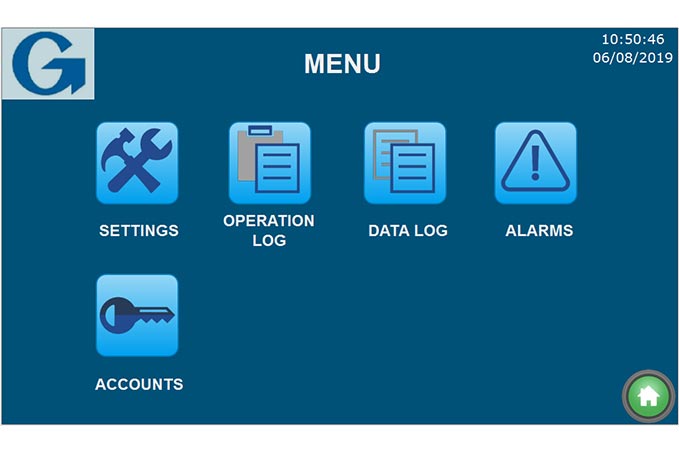

Automation and Controls

- Convenient and precise control of the Gansons inONERD using 10” HMI (Human Machine Interface)

- High-resolution LCD display facilitates easy visualization of process parameters in real time

- The interface is intuitive for a user-friendly experience

- Data can be transferred, saved, or directly printed by ethernet port through FTP

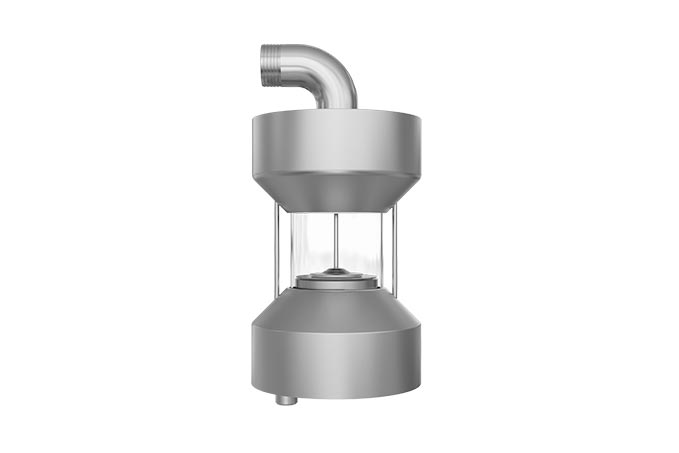

Gansons Fluidized Bed Dryer with Cyklon® Air Distribution System

The Gansons Fluid Bed Dryer comes powered with the global cutting edge in drying technology – Cyklon® Air Distributor System. The concentric rings with air-guiding channels on their underside provide a horizontal, spiral motion to the inlet drying air. The substrate is gently fluidized into a cyclonic pattern. This motion yields the following results:

• Drying at a fraction of the time compared to standard perforated air distributor plates: maximum drying efficiency

• Less inter-particle attrition means less granule breakage

• Push-pull system for controlled fluidization

• Uniform drying for sharper end point detection

Gansons Blenders

Four blender types can be interchangeably used on the central drive (V-Blender, Double-Cone Blender, Bin Blender, Octagonal Blender)

Safety

Appropriate precautions have been taken to ensure the Gansons inONERD is safe to use over long, continual operation. Several safety interlocks have been put in place to mitigate risk to the operator and product with the help of limit switches, sensors, and intelligent software.

Capacity Range

150-300g nominal capacity

Compliance and Certifications