Gansons Nauta® – Conical Screw Mixer

The Nauta® Mixer is one of the most versatile mixers and processors ever invented. The Nauta effects gentle, thorough, three-dimensional mixing of a variety of materials. The low-shear, low-heat mixer is particularly effective when mixing fragile, thermolabile material, with a wide range of bulk densities. The Gansons Nauta can be endlessly customised and adapted to be a granulator, processor, reactor, extractor, homogeniser… and finds applications in the pharmaceutical, food, personal care and chemical industries. The Nauta is seamlessly scalable and adaptable to nearly any mixing application.

Gansons is one of only three official licensees in the world for Nautamix B.V. (Holland). With 1,000+ Gansons Nauta® sold over 40+ years, Gansons has comprehensive experience across the broad range of applications that this extraordinary equipment can handle, making us a global technology leader in the food industry, chemical and pharmaceutical industries.

Our units are installed in manufacturing facilities regulated by US-FDA, UK-MHRA, EMA, WHO-GMP, Japan-PMDA, SAHPRA, MCC, TGA, MOH (various countries) and others.

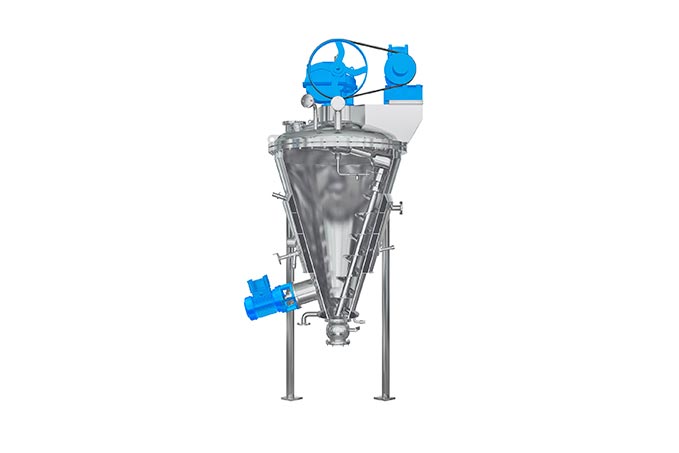

Three Distinct Intermixing Currents

• While orbiting the tank, the screw removes material away from the walls and deflects it into the centre of the tank.

• The Nauta's unique mixing screw rotates on its axis while concurrently revolving 360 degrees along the periphery of gently sloping product container.

• In effect, the material moves vertically across shear planes, as well as thoroughly intermixes at the particulate level.

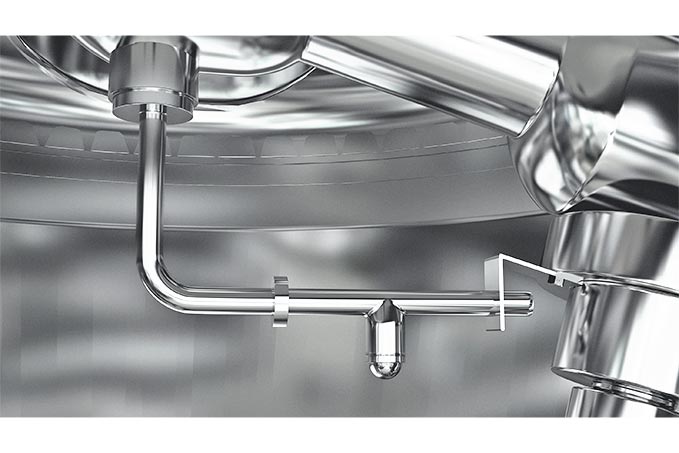

Liquid Addition

For incorporation of liquids (binder, flavours, fragrance) or moistening of dry solids through specially designed spray nozzles.

Sampling Device

Uniquely engineered sampling device enables in-line sampling.

Cleaning

• A WIP (Wash in Place) system ensures thorough cleaning and can be recipe driven based on defined cleaning protocols.

• 360⁰ rotating spray balls for thorough cleaning

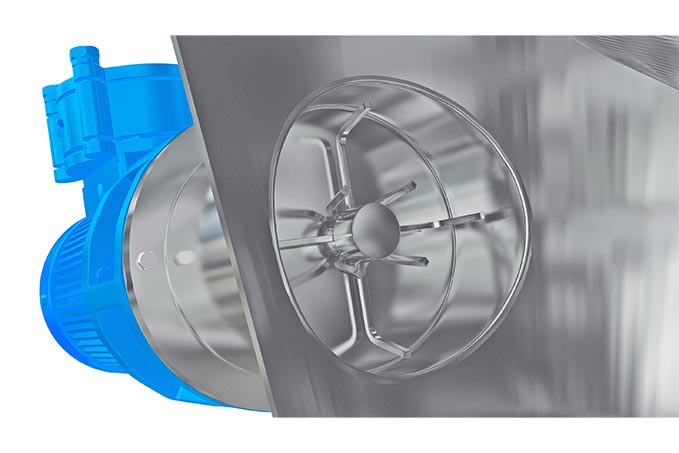

Lump Breaker

To gently disperse agglomerates and lumps which can develop in cohesive products.

Fast Complete Discharge

Rapid gravity discharge or side discharge.

Automation and Control

• Manual push button system

• Automated PLC based control system with touch screen HMI

Capacity Range

37 Standard models- 10L to 20,000L

Compliance and Certifications