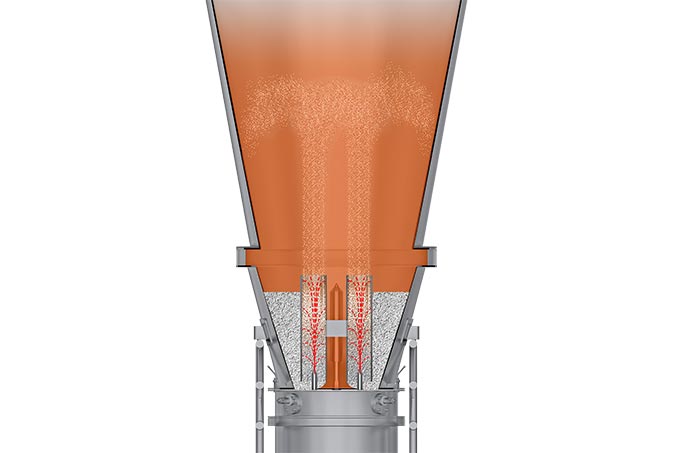

Fluidised Bed Processor and Coater (FBPC)

Our advanced, versatile Air Suspension Technologies are used for optimal drying, low-shear granulation and film coating of particulate substrates.

The Gansons FBPC:

- Ensures consistent and reproducible quality

- Designed per updated GMP and cGMP guidelines

- Seamlessly scalable from laboratory to production scale

- Designed to high safety standards

Our equipment is installed in manufacturing facilities regulated by US-FDA, UK-MHRA, EMA, WHO-GMP, Japan-PMDA, SAHPRA, MCC, TGA, MOH (various countries) and others.

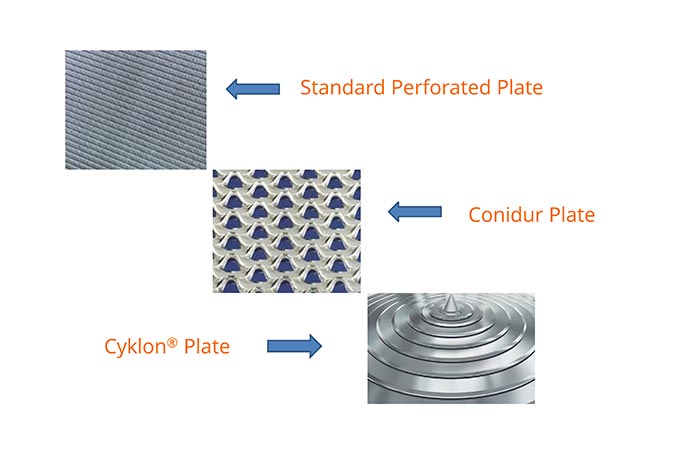

Air Distribution Systems

• Standard Perforated Air Distributor promotes uniform, vertical passage of conditioned air through aerated particulate material

• Conidur Screen enables lateral movement of fluidising air through particulate substrate and facilitates improved drying efficiency.

• Cyklon® Air Distribution System is the ideal Swirl-Flow® Air Distributor! The drying air enters the material bed nearly horizontally and achieves an ordered, cyclonic movement of particulate material. This optimises air-particle contact time and dramatically reduces drying time by up to 70%!

Air Handling Systems

• The precise quality, quantity and conditioning of drying air is attained from modular air handling.

• Humidification and dehumidification systems can be designed and provided based on requirement

Intelligent Automation

• Automated management of operation is facilitated through an ascending performance range of controllers (PLC and Human-Machine Interfaces)

• Pre-settable, precise control of process parameters

• Sensitive monitoring of process variable per pre-set frequency of measurement

• Calibrated sensors from globally recognised manufacturers

• Intelligent and timely alarms for set limits

• In-line with GAMP5, CE advisory

• Electronic data recording in compliance with USFDA 21CFR-Part 11

Available in deflagration/ safety designs for 2 Bar (with pressure) relief channel and 12 Bar pressure shock resistance (without relief channel)

Single/ Dual Filter Chamber Design

Filter bag or pulsed jet compressed air cleaning (depends on product and process)

Air Atomised Spray Nozzles

Compressed air assisted atomisation of fluids can be attained by suitable selection of spray nozzles and orifice diameters. The nozzles are anti-bearding, modular, robust and require minimal maintenance. Dosing is precise and can be validated.

Unique static charge dissipation system

Capacity Range

1L to 1,400L

Compliance and Certifications