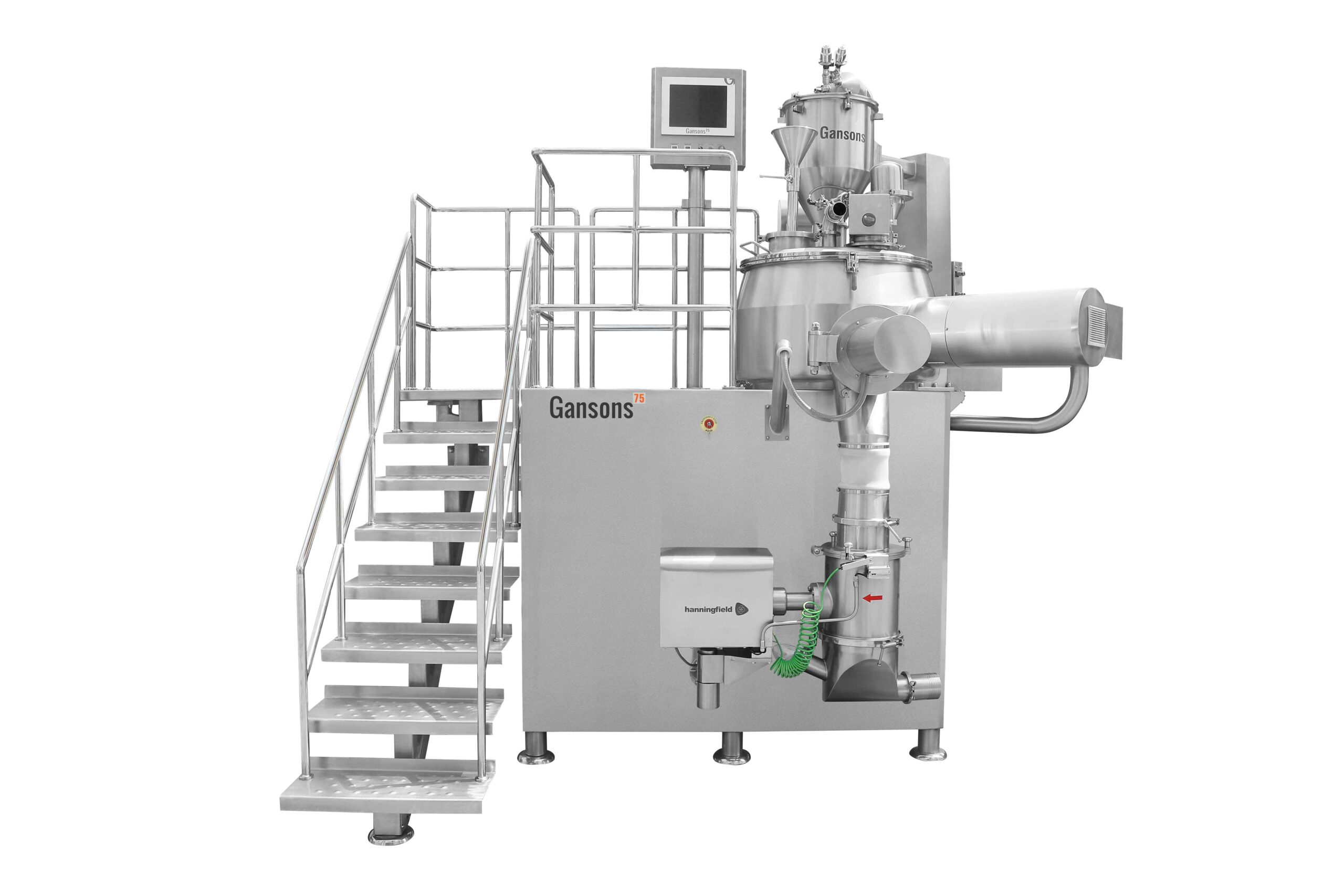

Leading High Shear Mixer Granulator (HSMG) Manufacturer

One of the best wet-granulation solutions in the industry today, the Gansons Manufacturer of High Shear Mixer Granulator (HSMG), facilitates effective and extremely rapid solid-solid or solid-liquid mixing, kneading, and granulation to produce uniform, high density granules.

Each component of the Gansons HSMG is designed to mitigate practical processing problems and prevent unforeseen downtime.

- Bimodal behaviour of powders? We have the solution.

- Black particles in your granules? The Gansons HSMG solves that.

- Irregular end-points? You will not get those in the Gansons HSMG.

We make wet-granulation efficient, predictable, scalable and trouble-free.

Our units are installed in manufacturing facilities regulated by US-FDA, UK-MHRA, EMA, WHO-GMP, Japan-PMDA, SAHPRA, MCC, TGA, MOH (various countries) and others. Upon request, our equipment is engineered to conform to CE, UL, ATEX, EU 2006/42/EC, ISO, and IEC norms. High Shear Mixer Granulator meets special needs for tablet formulation. Designed to meet the needs of drying of Pharmaceuticals, formulations & bulk drugs.

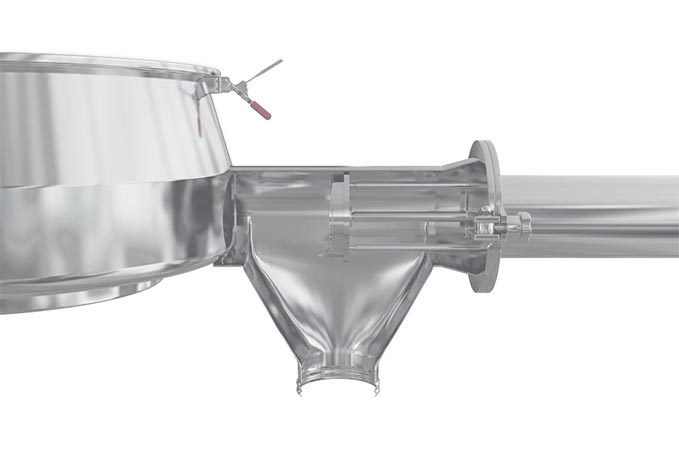

Process Bowl

The process bowl geometry of the Gansons High Shear Mixer Granulator is designed to eliminate dead spots during mixing, while aiding product vortex into the shear zone. For in-process heating or cooling, the bowl can be jacketed for thermic fluids.

Cleaning and Maintenance

• The Gansons Impel-lift system raises the bottom impeller for ease of cleaning

• 360-degree spray nozzles facilitate washing in place, and can be recipe driven

Construction Features

• 12-Bar shock pressure resistant designs available

• ATEX rated (flame proof) designs based on zoning requirements.

• All components are compliant with a Zone 2/22 production environment.

• All contact parts in SS 316L or FDA approved materials (gaskets, seals, filter bags etc.)

Impeller

The proprietary impeller effects optimal sheer and compression of powdery material as well as the formation of homogenous granules of targeted densities. The rake angle is optimized for ideal shear delivery and swept volume. The impeller’s close tolerance design reduces material build-up in the crevices.

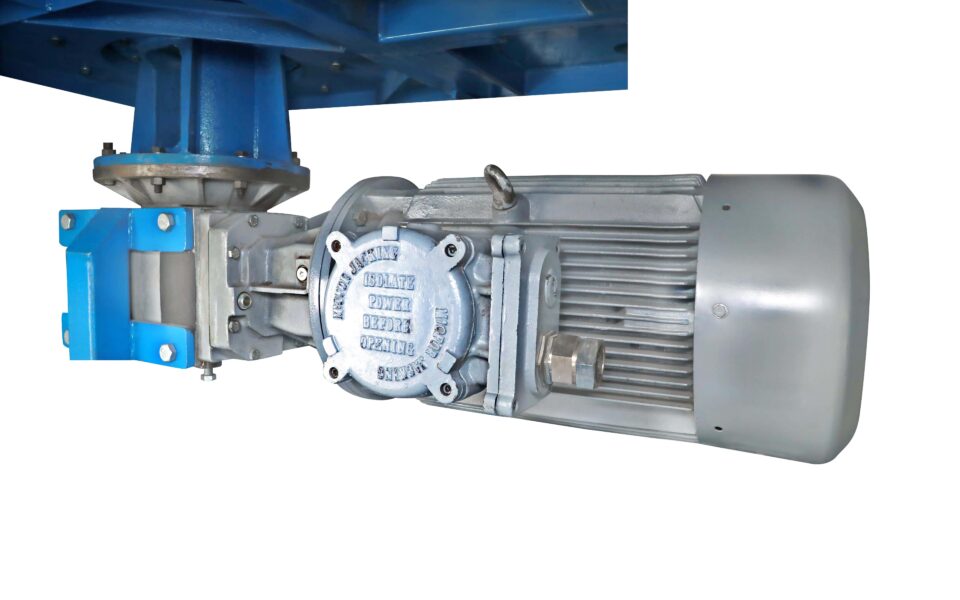

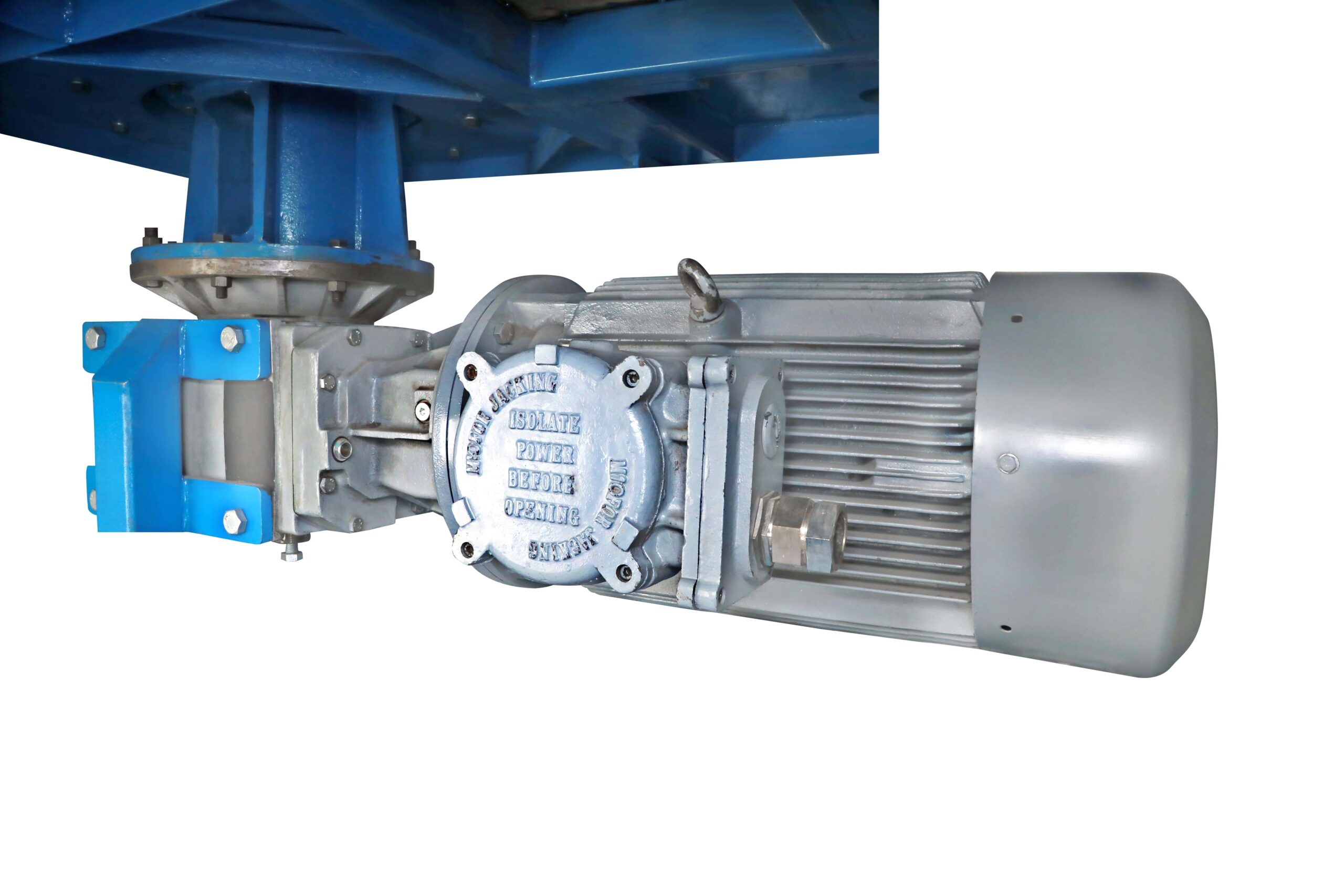

Gearbox

The gearbox assembly ensures over 95% torque transmission.

Duo Seal System

Our proprietary seal system design prevents the ingress of any particles into the shaft.

Chopper

Our uniquely designed chopper performs dual functions. It aids in binder fluid distribution throughout the dry mix while effectively delumping oversized agglomerates. The chopper facilitates material movement across shear planes, resulting in enhanced mixing.

Intelligent Automation

• 21-CFR part 11 compliance for data integrity and storage

• Internet of Things enabled

• Smart graphs for lot reproducibility

• Responsive, ergonomic, intuitive interface

• 3-modes with multi-level password access

Capacity Range

19 Standard models available from 1L to 2000L

Compliance and Certifications