Tablet coating is a crucial process for oral solid dosage (OSD) facilities. Recognizing the diverse needs of manufacturers and the unique configurations of their factories, The GansCoater series offers 40 distinct models tailored to meet the customized requirements of individual facilities.

At Gansons, we believe in the philosophy of creating machines that seamlessly integrate with pharmaceutical facilities’ existing infrastructure. This mindset marks a departure from the conventional approach of one size fits all, offering practical and efficient solutions for pharmaceutical manufacturing.

Our Legacy

With over 1600 machines in operation across 40+ countries, The GansCoater is the world’s #1 selling tablet coater.

Watch our history video to learn more about our journey.

Get Quote

Versatility of The GansCoater

The GansCoater’s 40 models are engineered to address specific needs and challenges. This ensures that regardless of the complexity or uniqueness of tablet coating requirements, The GansCoater series has a solution in place.

Customized Solutions:

40 models designed for specific requirements.

Interchangeable Design:

Cover batch sizes from 7kg to 400kg with two machines.

Optimized for Cost-Efficiency and Scalability

Seamless Integration:

Designed to fit into existing infrastructure.

Integrated WIP

PLC/IPC-SCADA based systems for 21CFR11 compliance (GAMP5), IoT enabled

Applications We Master

The GansCoater series is designed to excel in various coating applications:

Multi-layer Functional Coating

Enteric Tablet Coating

Film Coating

Sugar Coating

Tablet Polishing

We have helped one of our customer produces up to 2TONS of sugar-coated tablets everyday on a single machine.

Achieve:

- Uniform Colour & Appearance

- Zero Bloom or White Patches

- Time Efficiency

- Brilliant Gloss

- Consistent Weight Build-Up

The same customer produces up to 3TONS of film coated tablets everyday on the same machine on other days.

Achieve:

- Speed and Efficiency

- Uniformity and Consistency

- Large Batch Process Mastery

- Scalability from existing processes

- Versatility

Leading Pharmaceutical tablet manufacturing companies choose GansCoater as their preferred equipment for tablet coating application.

Feasibility Studies

40 grams to 400 grams

Research and Development

400 grams to 5 kg

Pilot & Exhibit Scale

7 kg to 75 kg

Interchangeable model

40 Kg to 400 Kg

Production level models

75 kg to 400 kg

High volume production

400 kg to 1000+ kg

Through-wall configuration

All Production models

High containment model (OEB3-5)

All Production models

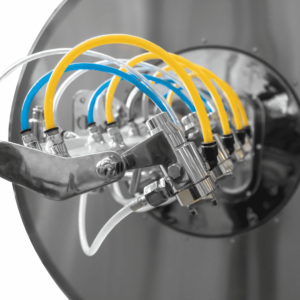

GHPN III Nozzle vs Standard Nozzles

Compliance and Certifications