The Gansons planetary VJHSE mixers and ointment plants can mix, emulsify, blend, de-aerate and distribute a wide variety of materials of different viscosities, textures, and sizes.

Adhering to cGMP norms, our equipment can handle capacities from 4L to 2500L. The preparation skids include fully automated vessels that can be integrated with a SCADA package, and other transfer systems for filling line interface.

Gansons planetary VJHSE mixers and ointment plants are the perfect solution for all your semi-solid cosmetic mixing needs. Our versatile equipment can handle a wide range of materials, from light and fluffy to thick and viscous.

Applications

Creams

lotion

Shampoos

conditioners

toothpaste

Hair Dyes

Capacity – 4L to 2500L

Get Quote

Additional features that make cosmetic production easy:

– Complete CIP/SIP system for thorough cleaning and sterilization.

– Precise shear control for consistent product texture.

– Custom recipe cycle design through our automation expertise.

– Contra or Semi-contra agitators for optimal mixing efficiency.

– Vacuum application capability for specialized processes.

– Jacketed anchor with PTFE side-scraper for improved heat transfer and product handling.

– Option to incorporate two planetary beaters in a single design for increased productivity.

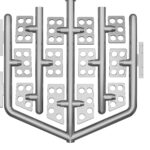

VJHSE Planetary Mixer

Our vacuum jacketed high-speed emulsifier ensures optimal mixing and consistency.

Ointment Preparation Vessel

This versatile vessel allows for efficient processing of your cosmetic formulations.

Compliances and Certifications