Why is the Nauta mixer most suited for pigment manufacturing?

Better mixing efficiency

Whether in pharmaceuticals, cosmetics, food processing, or chemical manufacturing, the quality of the final product often depends on the effectiveness of the mixing process.

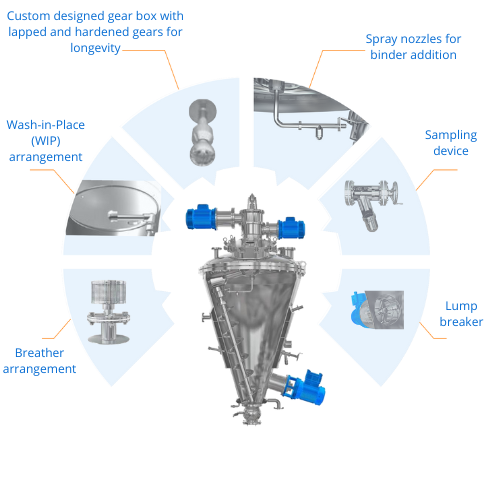

The Gansons Nauta mixers offer superior mixing efficiency, thanks to their gentle, low-shear mixing action ensures thorough blending and homogenization of powders, granules. This results in enhanced homogeneity in the final mixture, a critical aspect of pigment production. Additionally, their low-shear nature minimizes product degradation and preserves colour intensity.

Easy cleaning for batches

One of the primary challenges in batch production is the risk of trace colour elements of previous pigments contaminating subsequent batches. Conical mixers mitigate this risk through flood filling and comprehensive internal cleaning mechanisms, ensuring 100% coverage and preventing cross-contamination.

Easy to scale up

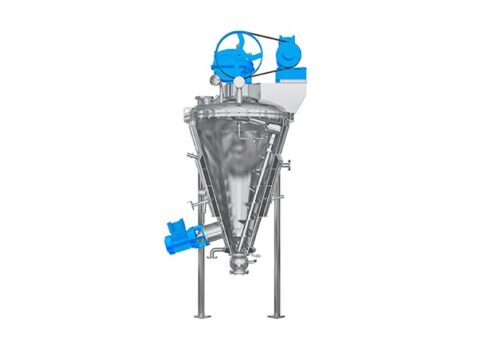

Scalability is another key advantage of conical mixers. Whether you’re starting with a laboratory model or scaling your chemical manufacturing and blending operations, conical mixers offer seamless adjustment of mixing capacity to align with your business growth.

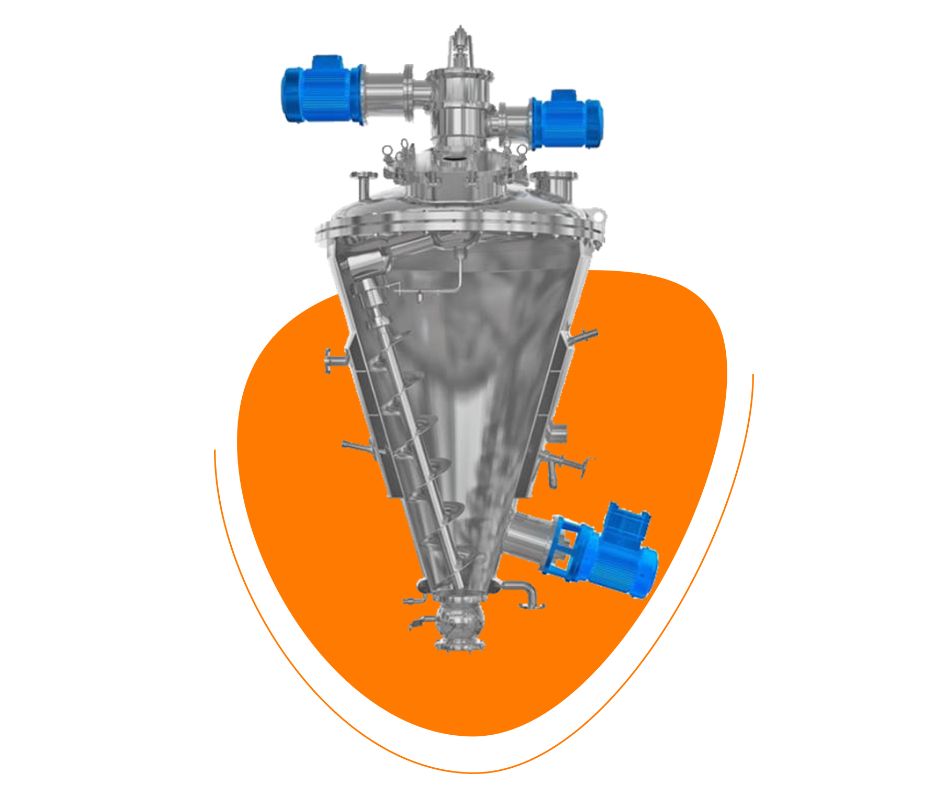

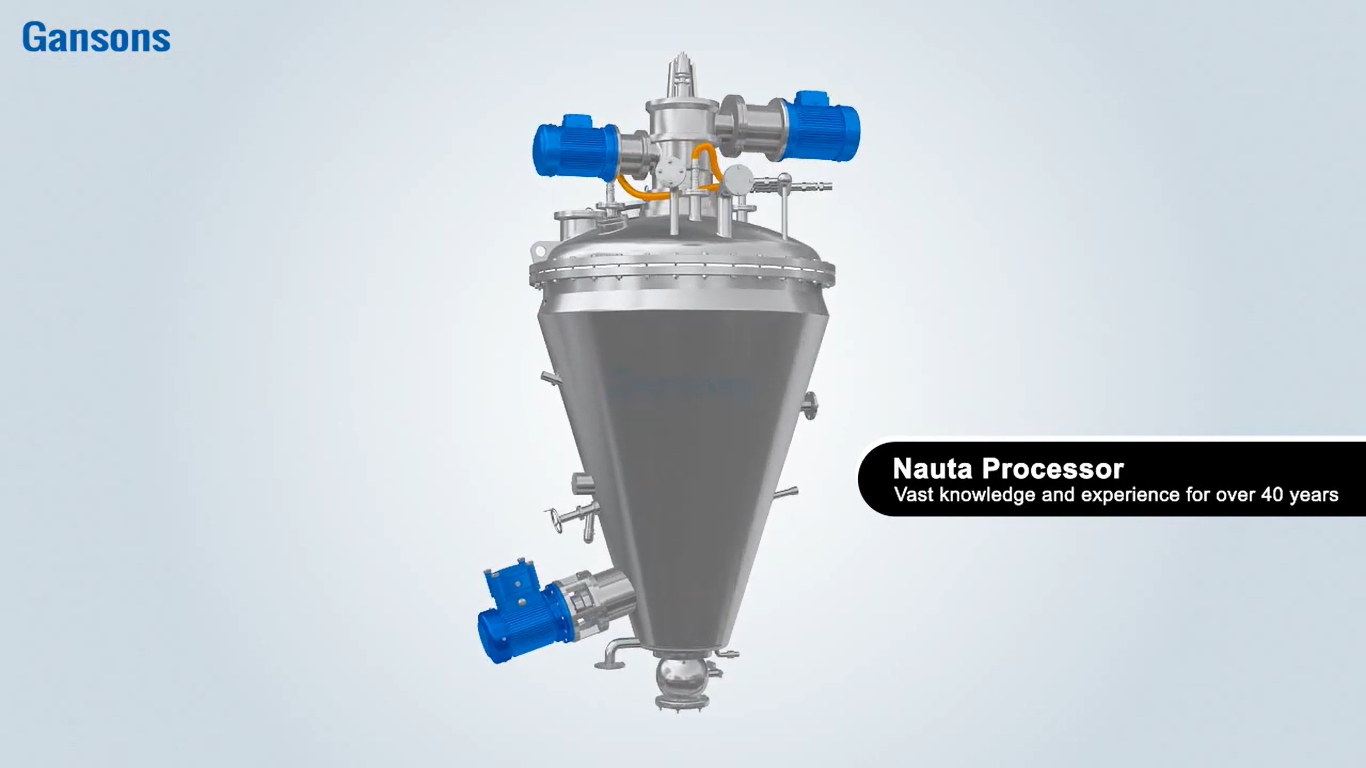

3 Dimensional Mixing with Nauta

• Mixing in all 3 axes

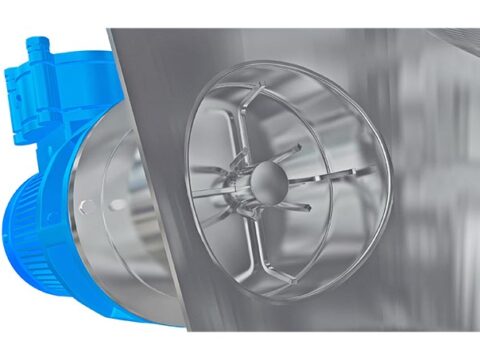

• Efficient mixing with no mechanical or thermal damage to product (filaments, flakes, oily organic materials)

• 95% Mixing efficiency; Mixing accuracy up to 0.01%

• Customised configurations to meet mixing needs

Capacity 10 L – 20,000 L (W configuration)

Compliances and Certifications