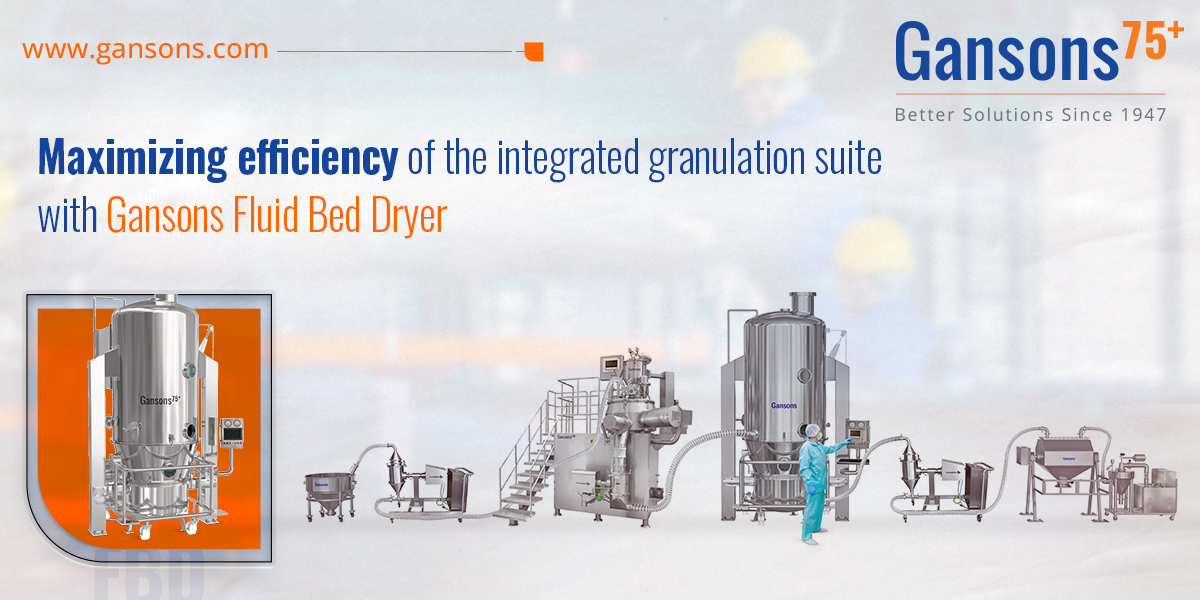

High Quality Fluidised Bed Dryer (FBD) Machine

Gansons Fluidised Bed Dryer (GFBD) is a top choice for fast and uniform drying of a multitude of products.

The GFBD is widely used in the pharmaceutical, chemical, food and allied industries to reduce the moisture/solvent content of particulate materials. The smart system combines best-in-class features with an intelligent automation platform to deliver reliable, safe, and sustainable performance over decades.

Our equipment is installed in manufacturing facilities regulated by US-FDA, UK-MHRA, EMA, WHO-GMP, Japan-PMDA, SAHPRA, MCC, TGA, MOH (various countries) and others.

Upon request, our equipment is engineered to conform to CE, UL, ATEX, ISO, IEC norms. The GFBD can be designed to code for shock pressure resistance up to 12 Bar.

Capacity Range

10L to 1,500L

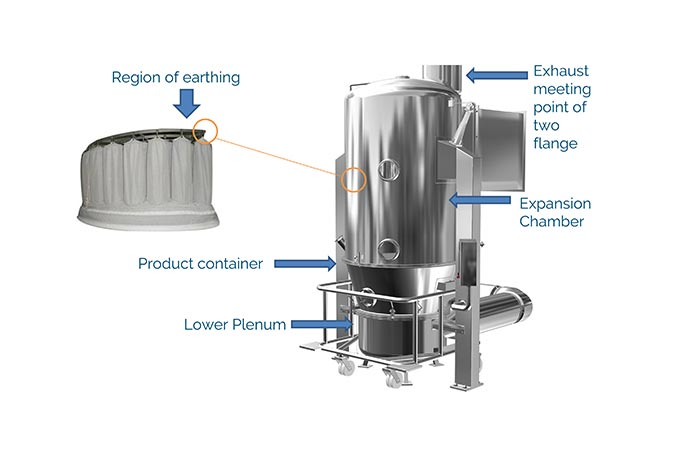

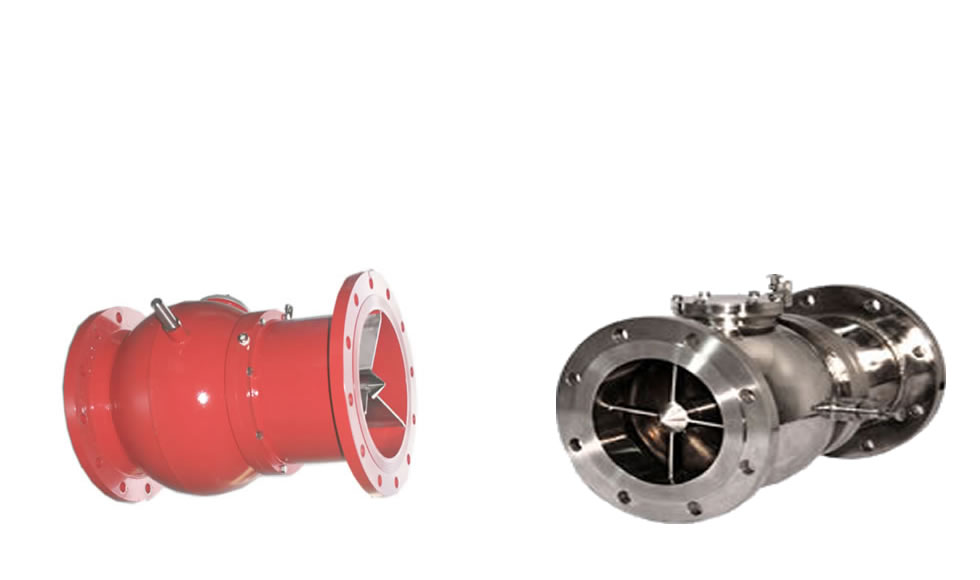

Cyklon® Air Distribution System (Patent Pending)

The Cyklon® air distribution system is designed to reduce the drying time and eliminate the largest bottleneck in granulation – long drying time. The Cyklon® is a proprietary design that represents the cutting edge of fluidized bed drying.

The unique air distribution eliminates the need for perforations—therefore it is easy to clean, assemble and maintain. The air is distributed in a swirl-flow pattern within the process chamber. The ordered motion of air prevents material stagnation, utility wastage and inter-particulate attrition. The result is an extremely rapid, uniform drying of material with negligible powder loss. The ‘push-pull’ fans allow sharp control of process parameters.

Among others, key benefits include:

• Up to 60%* reduction in drying time

• Negligible inter-particulate attrition: negligible product loss

• Easy cleaning

• Reduction of cleaning time by up to 90%

• Significantly lower utility consumption

• Up to 98%* yield

• Scalable from R&D to production

Unique 5-point electrical grounding system for product and operator safety

Intelligent Automation

• 21-CFR part 11 compliance for data integrity and storage, ALCOA+ compliant

• Pharma 4.0 enabled software, IoT enabled

• Smart graphs for lot reproducibility

• Responsive, ergonomic, intuitive interface

• 3-modes with multi-level password access

ATEX rated (flame proof) designs based on zoning requirements.

All components are by default compliant to a Zone 2/22 production environment.

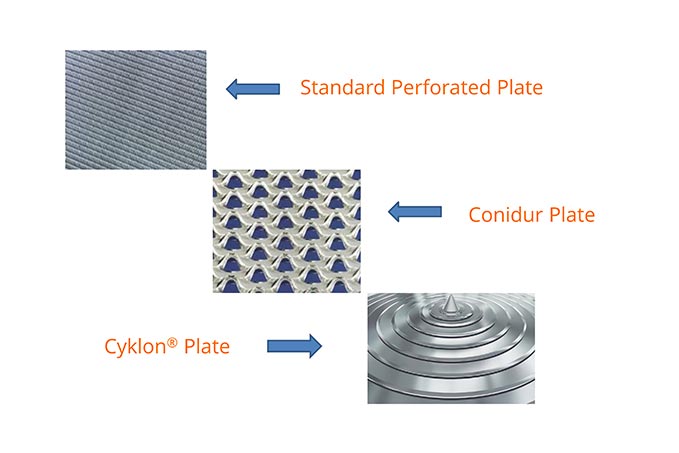

Air distribution plate types

12-Bar shock-resistant designs available for structural integrity and containment

Scalability

Meticulous attention to design provides reasonable prediction of operating parameters across capacities.

Other Features

• High-containment units for processing potent compounds (OEB 4 and higher)

• All contact parts in SS 316L, or FDA approved materials (gaskets, seals, filter bags)

Compliance and Certifications