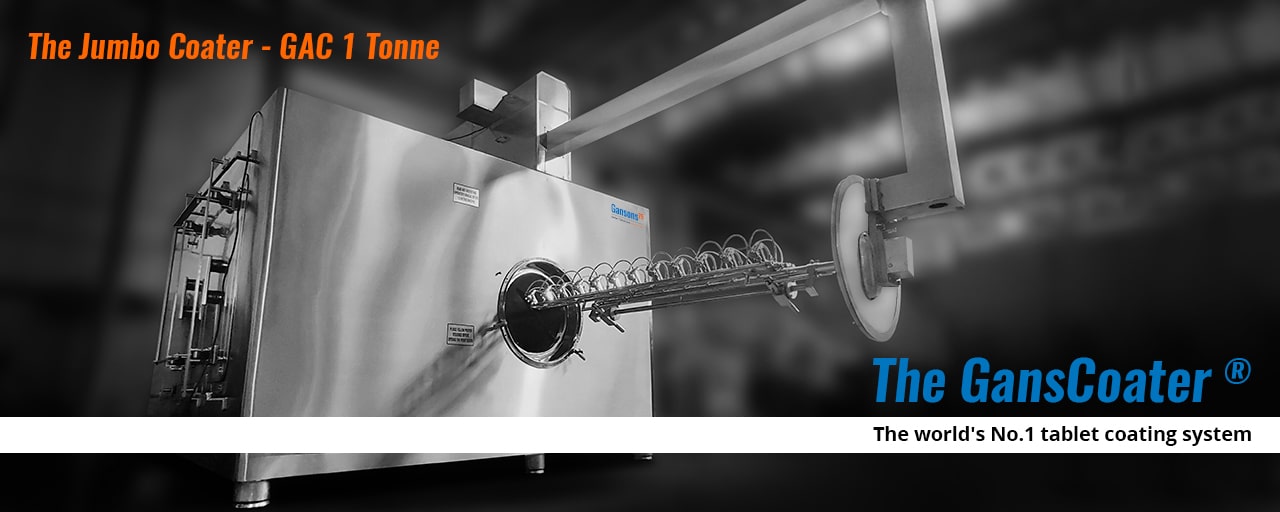

Tablet Coater – The GansCoater®

The product of four decades of coating experience, The GansCoater® is optimized for all types of tablet coating including Enteric Tablet Coating, Multi-layer Functional Coating, and Sugar Coating.

Testimonials

Cisen Pharmaceuticals

When one ventures into setting up a new R&D laboratory for OSD products, they do think about Gansons equipment as pharma scientists are most comfortable using them. Recently, we have procured the Lab model auto coater which excellently manages variable batch sizes while allowing us to perform both film and functional coating effectively.

Alkaloida Hungary

I really appreciate the job your team did upgrading The GansCoater® 900/800/600 control system. I know online installation due to Covid wasn’t easy but I knew you and your expert team would be able to do it.

Get Quote

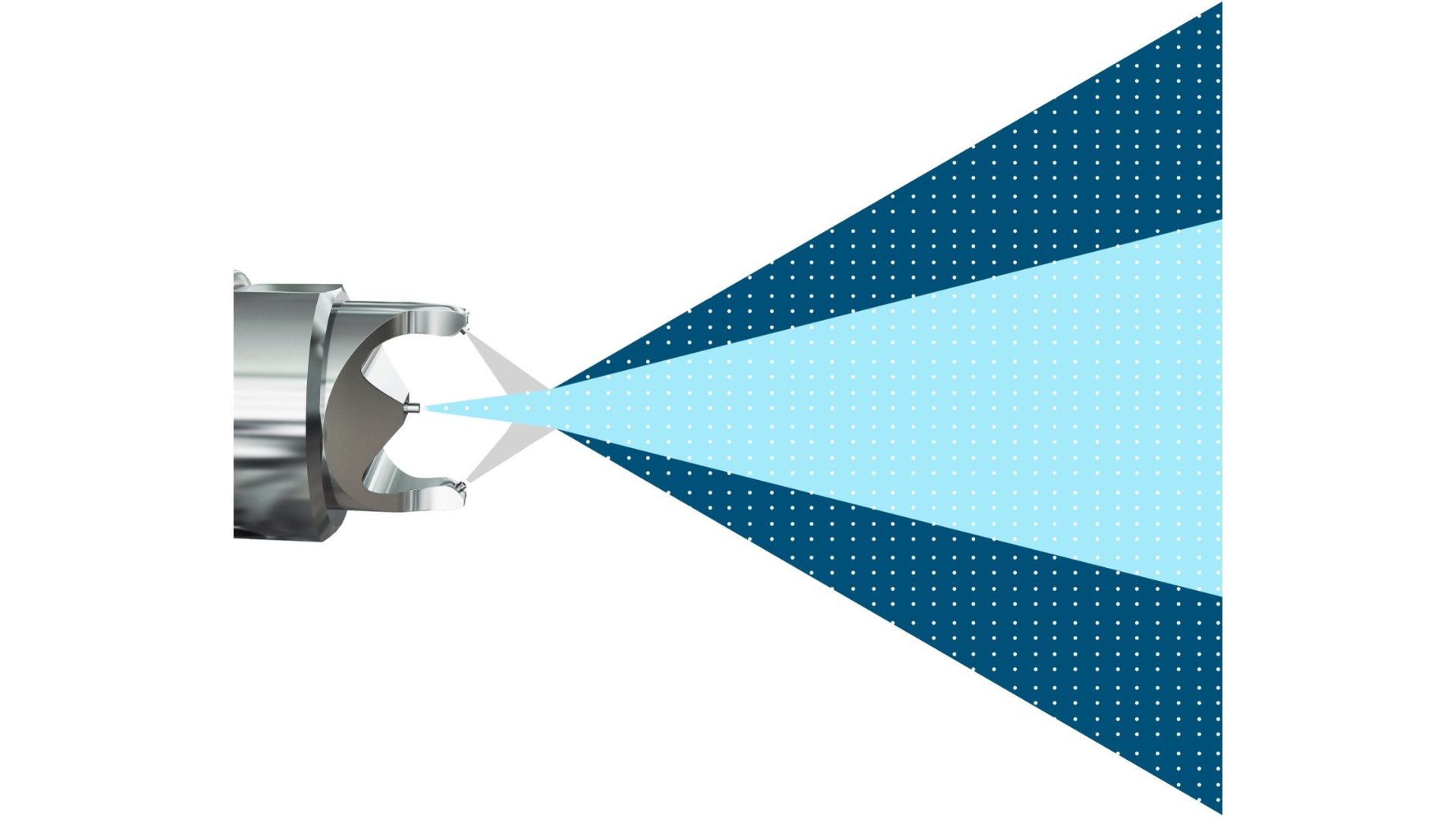

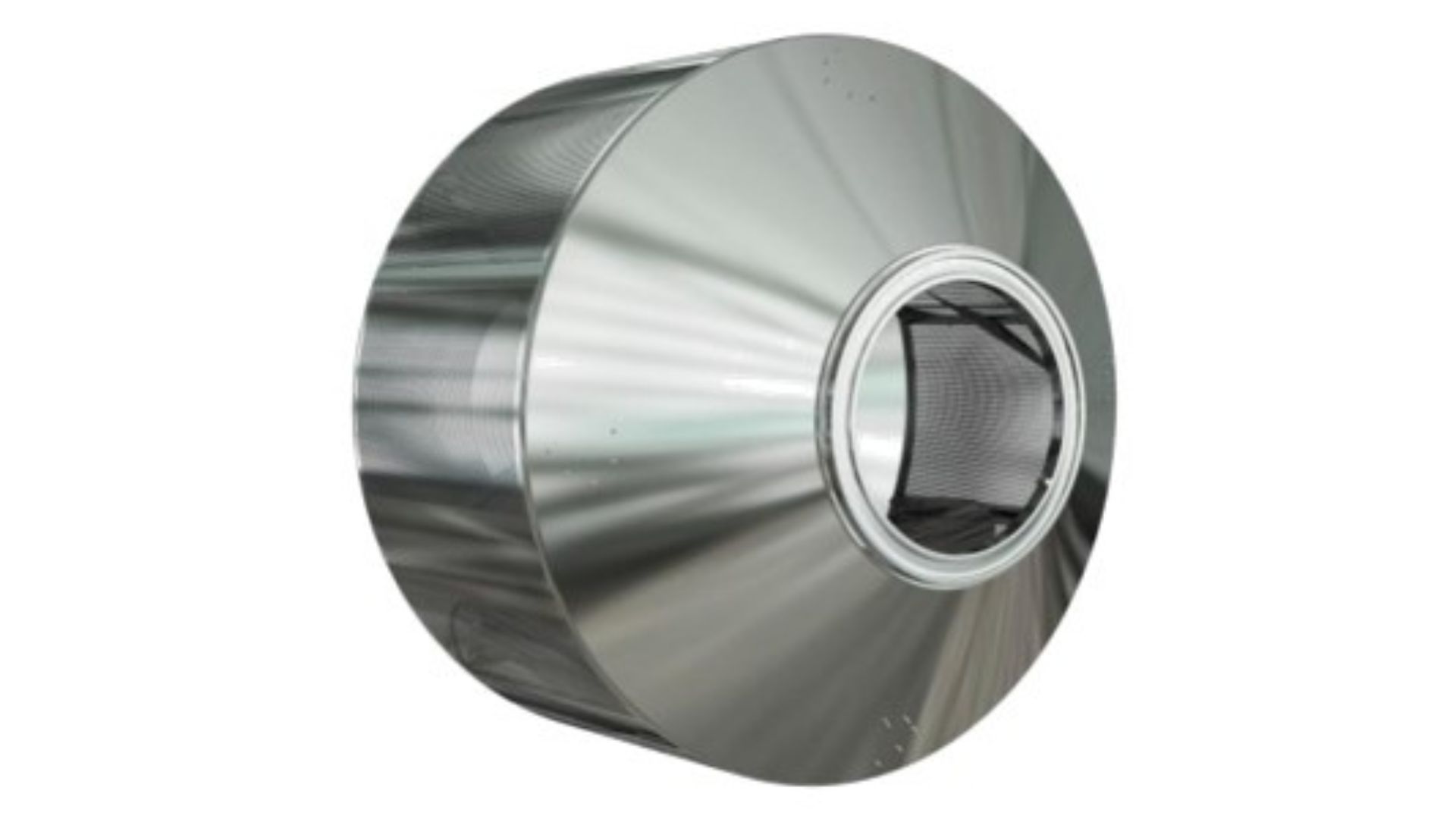

Proprietary GHPN-IIIRD spray nozzles

• Anti-bearding

•No elastomeric contact parts = easy to maintain + lower risk

•30% less compressed air consumption*

•Less than 5% spray losses

•Wide spray coverage with uniform droplet size

*compared to industry standards

Infrared Sensors provide accurate measurement and control over tablet surface temperatures.

• For accurate tablet bed temperature measurement

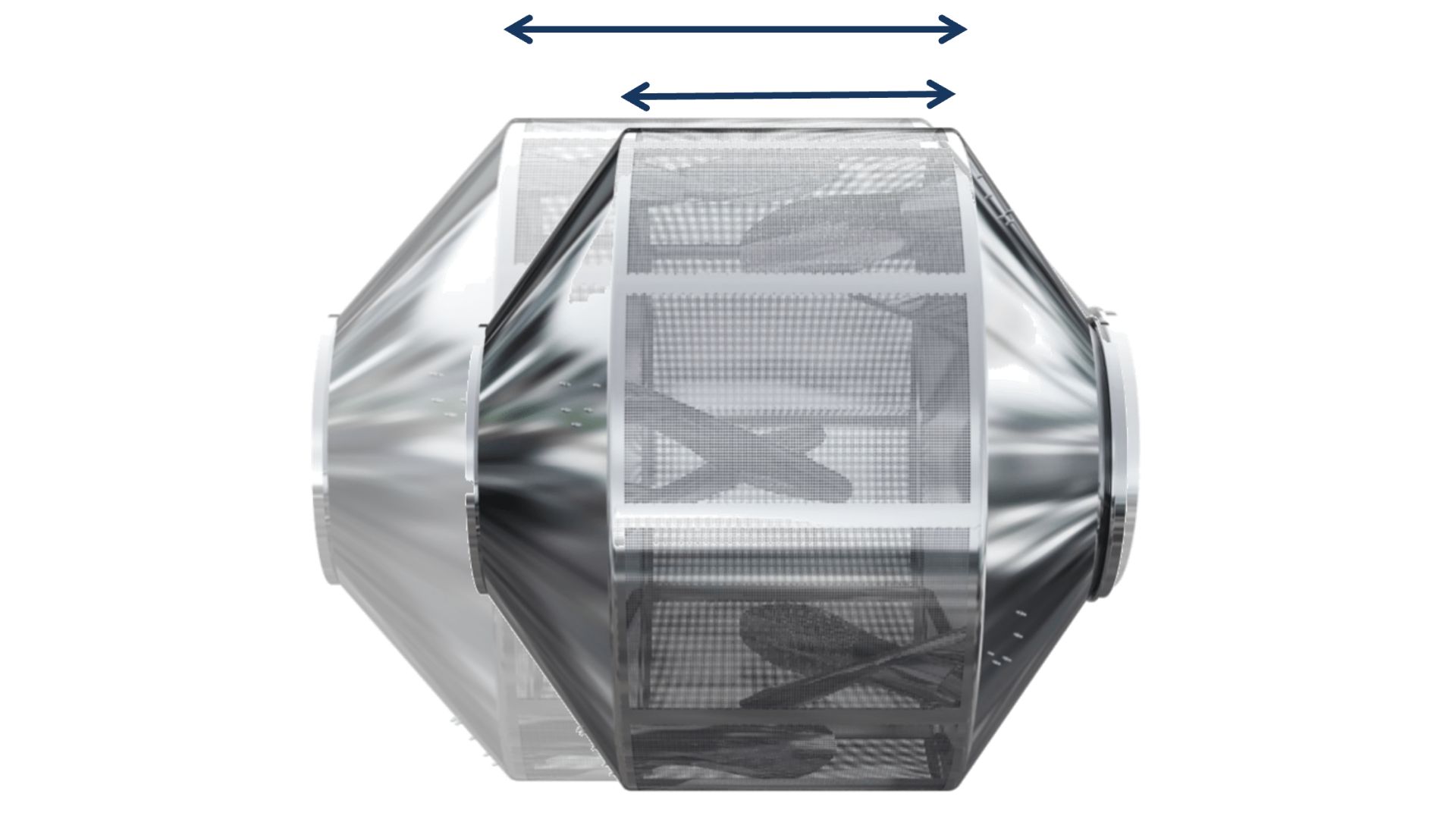

Astonishingly Smooth Coating Pan

• Less than 0.1 Ra value for defect-free tablet coating

•High open area for maximal drying efficiency

•Optimized pan geometry for fast and uniform coating

Gansons Aeroflo® Baffles enhance mixing and drying efficiency

Read more about how Gansons Rabbit Ear baffles offer superior mixing and tablet-turnover as compared to other types of baffles used in coating pans.

Interchangeable Coating Pans for flexible processing (less than 5 minutes downtime!)

• Flexible processing with large turndown ratio

• Easy 6-minute single operator changeover

Intelligent Automation for reproducible and risk-free processing

• PLC/IPC-SCADA based systems for 21CFR11 compliance (GAMP5)

• Internet of Things (IoT) enabled

• Customizable recipe management

• Multi-level access management

Ease in scalability from 500 kg to 1 ton with GansJumbo

Scalability to GansJumbo

Pan depth increased to maintain same tablet bed depth as GAC 1700 Ex. The best tablet coating machine along with enteric coating, sugar coating and film coating.

Evolutionary Design. Revolutionary Performance

- Widest spray coverage with small uniform droplet size.

- Reduces surface area around the fan jet. Significantly less bearding.

- Spray operations run up to 10 times longer with minimal nozzle build up.

Countersunk holes – For uniform drying

- Holes are countersunk to increase Venturi effect and hence drying efficiency

- Each perforated area completely electro-polished to reduce abrasion

- Easy to clean

- Only company to implement this feature

Compliance and Certifications